Metal roofing systems, made from pieces or tiles of metal, are characterized by their high resistance, impermeability and longevity.

When choosing an ideal metal roof, ensure that the product design is appropriate to your property’s construction. Select the material that compliments current styles, neighborhoods and locations.

Sabal Construction and Roofing LLC provides quality metal roofing materials with exceptional work and customer service. We operate diligently to maintain our 5-star rating.

Aluminum

Long Lasting and resistant to salt water corrosion.

Aluminum Metal roofing is largely recommended for properties in coastal climates since aluminum is salt corrosion resistant. The outer layer of aluminum reacts with oxygen in the environment to create a layer of aluminum oxide, which effectively seals the inner layers of the metal from future corrosion.

Aluminum roofs are often installed with a painted coating as it’s natural patina and are not typically thought of as aesthetically appealing. Aluminum roofing material’s strength-to-weight ratio is higher than steel, the factor of cost often results in panels that are too thin for their surroundings. In regions with high winds or strong environmental stresses, this can result in damage to the roofing material.

Properly identifying the environmental strains that an aluminum roof will face is crucial in choosing the right design.

Copper

Extremely long-lasting, very soft with low melting temperature.

Copper is an extremely long-lasting metal that in ideal environments, can last well over 200+ years. Copper roofs are 100% recyclable, making them wonderful green roof options.

Cooper metal creates the quietest metal roof since it’s extremely soft. The softer nature of Copper Roofing also means that in hail prone regions, it may be easily damaged. As a softer metal, hailstones easily dent the copper. With modern installation practices, all metal roofing now recommends proper substrates and insulation to minimize noise from rain or hail.

Steel

Three variations: galvanized, galvalume, and weathering steel (Corten).

Steel roofing is the most common material in commercial construction sites. Steel is the most recycled material and the least expensive. Steel’s primary advantage is it’s flexibility of use and cost.

- Galvanized Steel: The most common form of steel roofing material. Created by using a layer of Zinc to protect the inner layer of steel from corrosion. The coating extends the life of a steel panel and slows the corrosion process.

- Galvalume Steel: Made with a combination of Aluminum and Zinc. Aluminum better protects against corrosion and provides smaller, smoother spangle for a more identical appearance. Due to its Aluminum qualities, Galvalume offers better surface protection but is vulnerable to scratches or cut edges.

- Weathering Steel: Originally designed for heavy steel industry use like bridge construction. An outer layer of steel is designed to intentionally rust, protecting the inner layer of steel, and is not designed to be used as a structural solution for steel roofing. It is often used in accent roofs, or with the expressed understanding of the rusting process and the need for regular maintenance.

Tin

Often referring to steel, used prior to World War II. No longer commonly applied.

Tin Roofing is an often-requested item by enthusiasts around the United States. Tin was introduced as a canning material, which was then adapted by rural DIYers who flattened out the material and used it as a shingle when other materials were not available. “Tin roofing” in modern times, normally refers to either a galvanized steel or aluminum material rather than actual tin roof sheets.

Zinc

Extremely long-lasting, resistant to corrosion and lowest melting point.

Zinc is an astonishing metal that is able to use its patina to repair scratches over time and stay strong for over 100 years. The natural properties of Zinc make it a favorite for commercial projects due to its malleability and flexibility. While the chalking of Zinc over time is not considered appealing, it can be cleaned and controlled to an extent.

Zinc has a lower melting point than other roofing metals. This lower melting point means that Zinc processing for use as a building material requires less than a ¼ of the energy taken to process steel or copper. Zinc is 100% recyclable and available in most local markets, making it an extremely green material. The main downsides to Zinc are the chalking effects and the price.

Zinc, like most bare metals, does patina into a blue/grey appearance if left unpainted. Along areas where water flows, this often leaves a chalk residue that many find unappealing. Zinc is a very soft metal and can be easily damaged by hail or high winds depending on the panel or shingle design.

Southwest Florida's Leader in Roofing

Quality, durable and long-lasting roofing materials safeguard properties against weather elements and intrusions. Sabal Construction and Roofing LLC installs, repairs and upgrades residential and commercial roofs in Southwest Florida and the surrounding areas.

- Commercial Roofing

- Insurance Restoration Services

- Residential Roofing

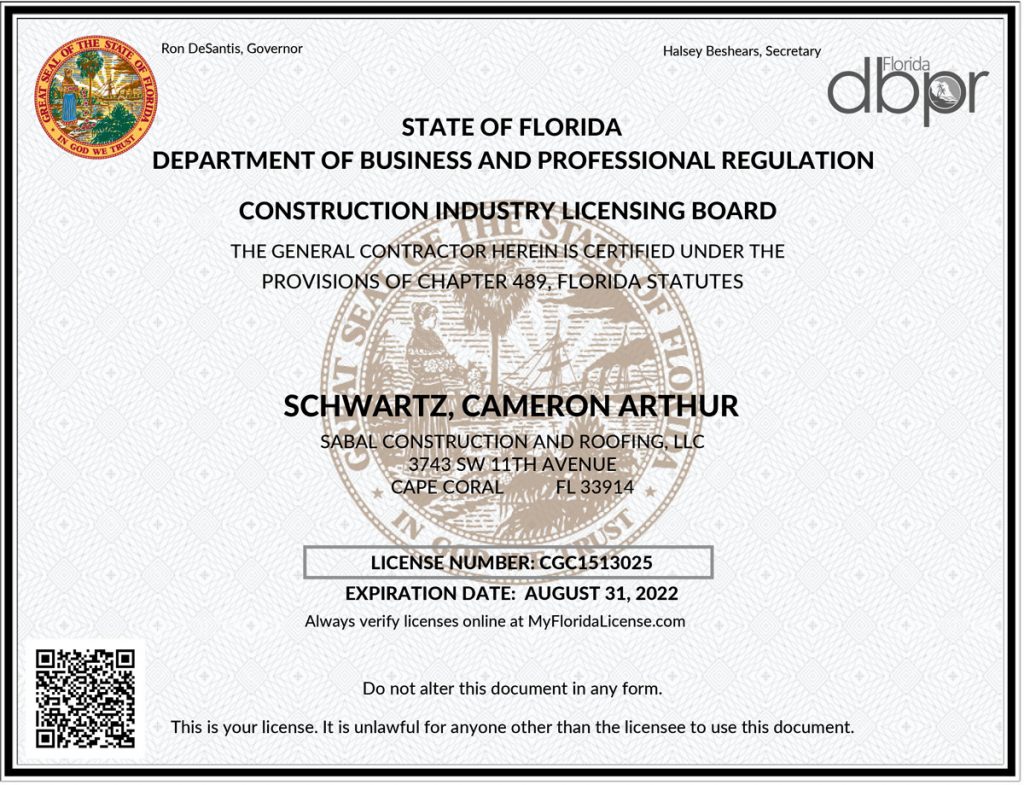

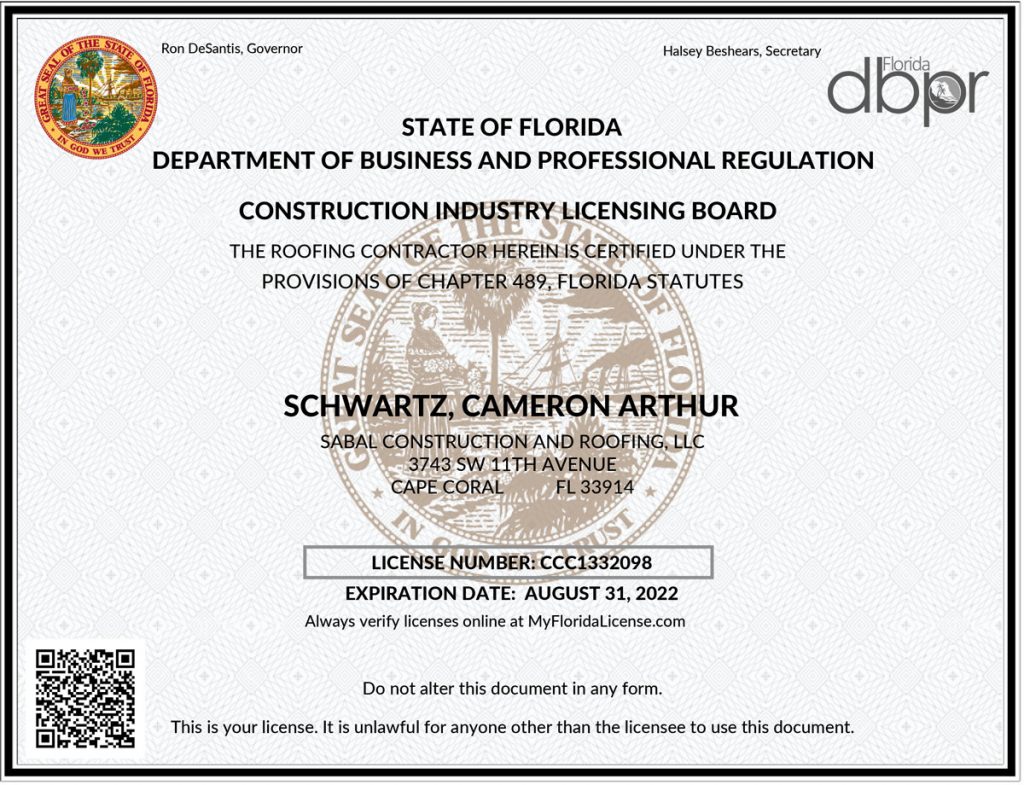

Licenses

Sabal Construction and Roofing LLC holds a Roofing License in addition to a General Contracting License. We ensure roof and restoration projects meet all required code standards.

Florida Certified General Contractor: License Number CGC1513025

Florida Certified Roofing Contractor: License Number CCC1332098

To discover more about premium roofing materials, call Sabal Construction and Roofing LLC at (888) 591-8559.